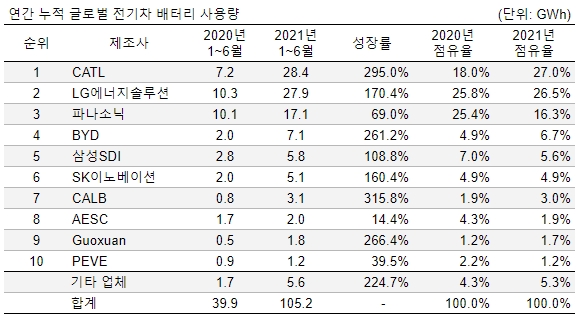

Batteries made by Chinese giant CATL was the most used in electric vehicles in the first half of 2021, followed closely by South Korean rival LG Energy Solution, according to data from market research from SNE Research.

CATL’s accounted for 28.4GWh from January to June, followed by LG Energ Solution’s 27.9GWh.

Panasonic of Japan ranked third with 17.1GWh and BYD of China fourth with 7.1GWh.

South Korean firms Samsung SDI and SK Innovation came in fifth and sixth, respectively, with 5.8GWh and 5.1GWh each.

Chinese battery makers showed the highest growth among the companies. Companies such as CATL, BYD and CALB saw triple shipment compared to the previous year.

Due to the US-China trade war, Chinese companies are aggressively expanding into Europe.

Their South Korean rivals showed the next highest growth rates as they are seeing rising demand in the EV market. LG Chem, the parent company of LG Energy Solutions, had said it plans to spend 6 trillion won in its battery business.

Samsung SDI is planning to spend 2 trillion won this year, while SK Innovation has previously said it will spend 18 trillion won up to 2025.

CATL had also said it plans to launch sodium-ion batteries in 2023. There are more reserves of sodium and they are cheaper compared to lithium. However, they have low energy density. CATL had said it plans to group a lithium iron phosphate (LFP) cells with sodium-ion cells to overcome the energy density problem.

Prime Planet Energy & Solutions, a joint venture between Panasonic and Toyota, had said it plans to lower battery manufacturing cost by 50% by next year.

LG Energy Solution is pushing NCMA (nickel, cobalt, manganese and aluminum oxide) cathode batteries to increase energy density. Less use of cobalt means it can reduce costs.

Samsung SDI has recently begun production of NCA cathode batteries which it says use 91% nickel. This will also lower cost and increase energy density.

SK Innovation is planning to supply NCM9, ½, ½ batteries to Ford. Instead of adding aluminum as a stabilizer like its rivals, the company is using Z-stacking production method.