The Korea Electrotechnology Research Institute said on Monday that it has transferred its technology on solid-state electrolyte production to Daejoo Electronic Materials.

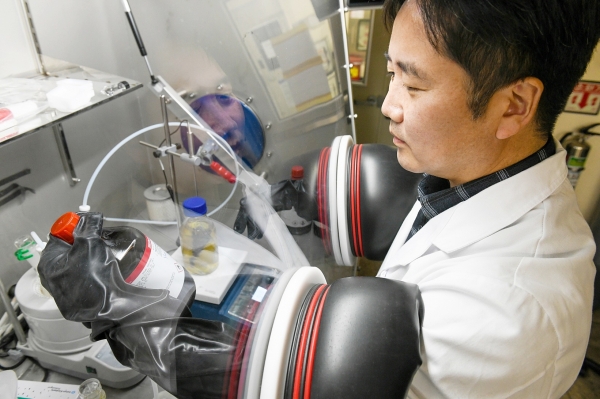

The technology was developed by principal researcher Ha Yoon-cheol is a precipitation method of production of solid-state electrolytes for use in sulfate solid-sate batteries.

Daejoo is planning to build a pilot line that will use the technology at its facilities at Siheung.

The company said it was also developing various silicon materials that can replace lithium metal anodes currently proposed for solid-state batteries.

Daejoo is the only company in South Korea that has commercialized silicon anodes for use in batteries.

The material mixes in silicon with graphite, which is currently widely used as the anodes in batteries.

Mixing in silicon can increase energy density by up to over three times, Daejoo had said. The company has been supplying its silicon anode to LG Energy Solution since 2019.

A fund, which LG Chem is a part of, has earlier this month invested 79.9 billion won into Daejoo, which said it will use the money to expand its silicon anode production capacity from the current 400 metric tonnes a month to 1,000 metric tonnes by next year.

KERI’s technology doesn’t use the relatively expensive sulfate lithium.

It uses a simpler liquid synthesis process to mass produce sulfate solid-state electrolyte, the institute said.

Sulfate solid-state electrolyte has high ion transferability and is flexible, making the design of the separators that can be used with to be easier.

KERI claimed its method can reduce production costs by 1/15.