Caused by power shortage in China

South Korean display and fab equipment makers are suffering from increased lead times for key components they need to make equipment with, TheElec has learned.

If the issue is prolonged, the companies may face delays in delivering their equipment up to the second half of 2022, which may affect the ongoing chip shortage, sources working at these companies told TheElec.

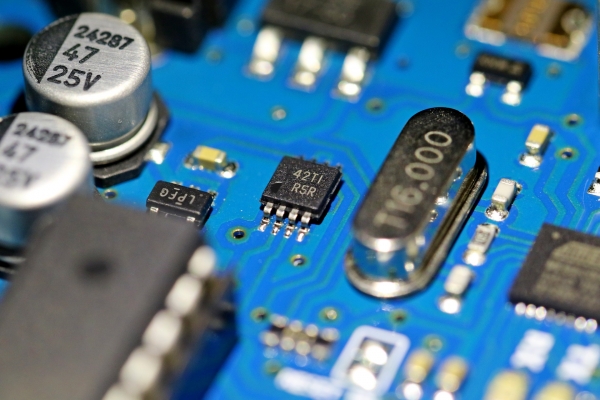

Display and fab equipment use components such as vacuum pump, motor, accelerator as well as various pipes and valves.

The lead times for these parts are usually a week, the sources said.

But this has been extended to eight weeks, they said, while come of the component’s lead time has been delayed to up to six months.

The shortage in these mechanical components was happening not just in South Korea but globally, one of the sources said.

For example, equipment companies are paying particular attention in procuring motors as they are mostly made by Japanese companies, making it difficult for them to be flexible in their procurement.

Sources said the cause of this component shortage is due to the power shortage in China and the recent earthquakes in Taiwan, which have affected the part suppliers.

China is limiting power supply to reduce their carbon emission rate, which is affecting the production output of Taiwanese part firms that have factories in China, they said.

These developments have also caused raw material prices to go up, they added, worsening the situation.