Samsung Electro-Mechanics has developed five new multilayer ceramic capacitors (MLCC) for automobiles, the company said.

Three of them are for vehicles’ powertrain system and two others are for anti-lock braking systems (ABS), Samsung said.

Ceramic capacitors allows electricity to flow consistently and stably on electronic circuits. It is used widely in electronic devices.

Vehicles have around on average 3,000 to 10,000 MLCCs installed on them for their powertrain, safety, driving and infotainment systems.

Samsung’s three powertrain MLCCs are: 2.0mm x 1.2mm 1.0 micro Farad (uF), 3.2mm x 1.6mm 2.2uF and 3.2mm x 2.5mm 4.7uF.

The MLCCs can be used stably even at high voltages of up to 100 volt (V), the company said. More vehicle systems are migrating from 12V to 48V, Samsung said, and the new MLCCs will meet demands in automobile batteries, 5G networks and solar power systems where high voltages are required.

On the new MLCCs for ABS __ which comes in 2.0mm x 1.2mm 4.7uF and 2.0mm x 1.2mm 2.2uF versions __ Samsung said they last 20% longer than their predecessors and have 5% increased DC bias. DC bias refers to the characteristic in which higher voltage application decreases the device’s capacity.

The MLCCs also withstand voltages 1.5 times higher than their predecessors, the company said.

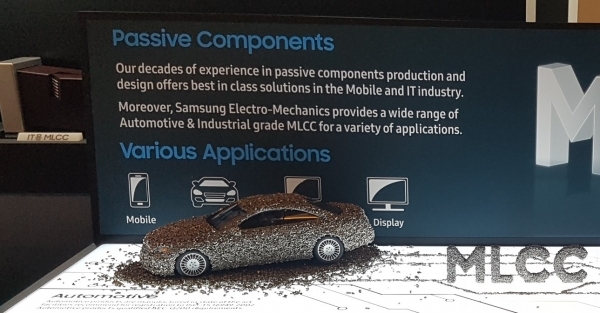

Samsung Electro-Mechanics have been developing and producing MLCC since 1988. It began making those for industrial use and vehicles in 2016. It built a new MLCC factory line in Busan back in 2018 to make those aimed at auto-component applications. It is building a new MLCC factory at Tianjin, China.